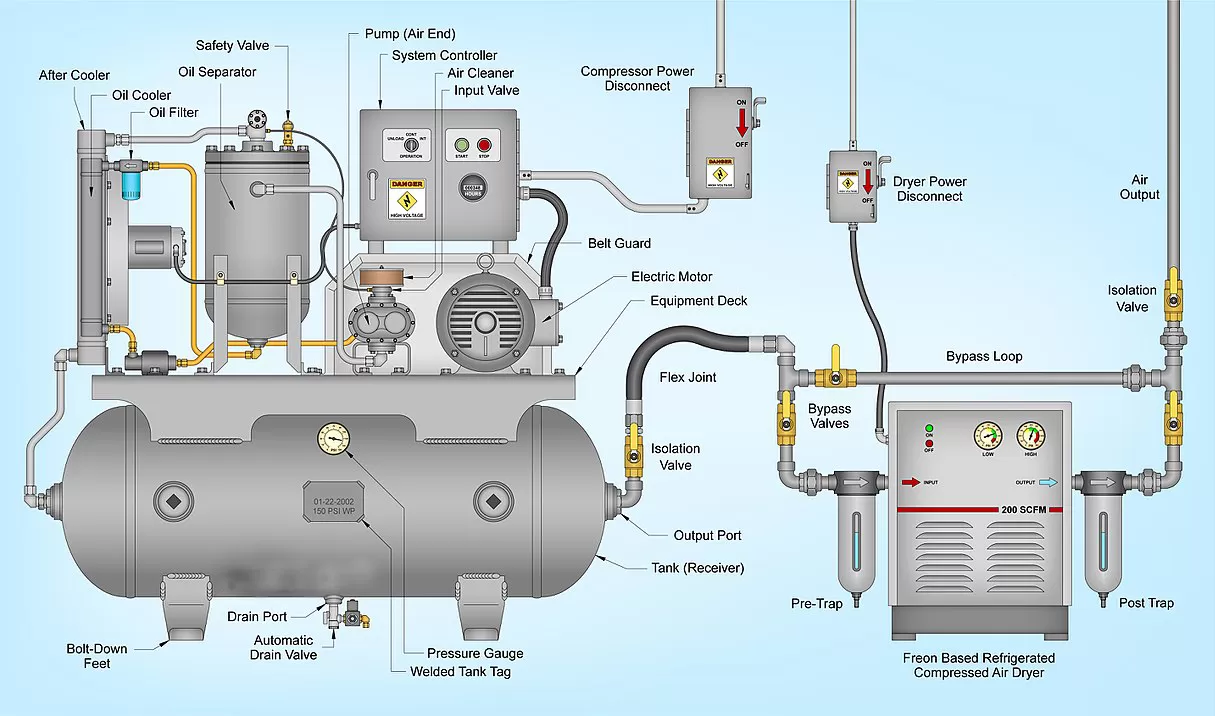

Do you know that the environment of the screw air compressor station and air compressor room is very important for the stable operation of the screw air compressor station? Good operating environment of screw air compressor station can reduce most equipment failures.

Below 4 things needs to be keep away from them to make sure the stable operation of rotary screw air compressor station:

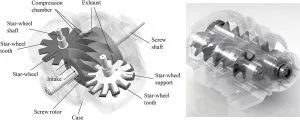

- Keep away from dust: The screw air compressor room with a lot of dust will first cause the air filter to be blocked, and the air cooling effect is poor. The dust will enter the oil circuit system, and the service life of the three filters will be greatly reduced. The dust particles will also cause rotor wear, bearing wear, and abnormal noise.to keep away from dust is very important for the long term stable operation of screw air compressor station.

- Keep away from high temperature: the poorly ventilated room will affect the heat dissipation of the motorin compressor, resulting in the high temperature operation of the air compressor, which will short the service life of the electric parts and affect the service life of screw air compressor station too.

- Keep away from corrosive gassurrounding: in addition, corrosive gas will also bring many hazards to pipelines and rotors. It will corrode and damage the male and female rotors, causing leakage and easy to corrode the pipeline.

- Keep away from humidity: Do not operatethe rotary screw air compressor in an environment with too high humidity. Moisture can not only corrode the casing of the rotary screw air compressor, but also emulsify the lubricating oil when the moisture in the air enters the screw air compressor with the air, thus reducing the lubrication effect and accelerating the corrosion of mechanical moving parts.

If you are facing a lot of problems in screw air compressor room and screw air compressor station, please follow us Kotech or discuss with Kotech professional team, we will share more information with you.