Avoid Unnecessary Waste In The Use Of Air Compressors

Air Compressor is one of the most widely used in the industrial field, because of its safety, pollution-free, good regulation performance, convenient transportation and many other advantages, so that it is more and more widely used in the field of modern and automatic force. Compressed air is also an expensive energy power source, and continuously reducing the overall operating costs of compressed air is an important issue for every plant manager. After the compressed air is discharged from the compressor, it needs to be transported through the air tank and line to the use of the application. If the pipeline leaks during the compressed air transmission, it will cause the energy consumption of the air compressor to increase, resulting in unnecessary waste.

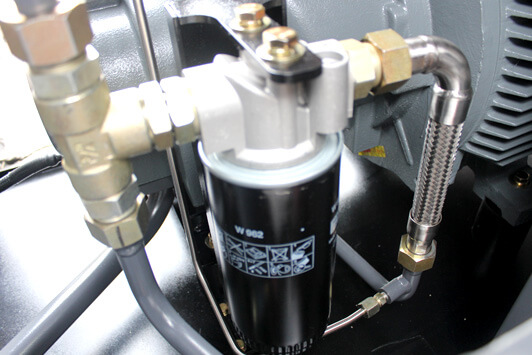

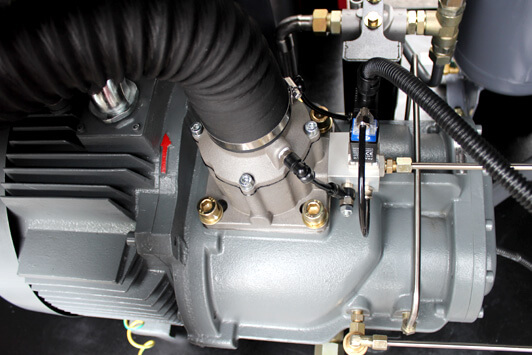

But for safety, KOTECH screw air compressor will check every detail before leaving the warehouse, and provide relevant proof, such as the Industrial air compressor in the following figure, its pipes use stainless steel, to avoid rust and leakage problems, we will also check each parts before leaving the warehouse.

Analysis of the causes of corrosion leakage in air compressor pipelines:

The leakage source of compressed air is mainly formed by aging and damage by external forces during the use of pneumatic components, such as cracks in various pneumatic pipelines, leakage holes, pipe joint wear, valve element seal damage, cylinder seal wear. The cost of compressed air is high, the proportion of leakage is large, and the loss caused by leakage is often beyond the imagination of most people.

Businesses generally use traditional patching methods:

Patch welding, punching cards or making pipe hoops, replacing seals, sealing glue leak plugging and so on.

The above operation technology can solve some pipeline leakage problems within a certain range, but for some pipelines with flammable and explosive media, in the face of complex construction environments and urgent construction time requirements, the traditional repair methods are difficult to meet the needs of enterprises, in this context, Solei carbon nanopolymer material on-site plugging technology can be used.

This technology makes full use of the material’s advantages of fast fixation, temperature resistance, corrosion resistance, pressure resistance, etc., and effectively treats on-site leakage. Especially in flammable and explosive occasions, the on-site treatment of low-temperature and low-pressure equipment pipelines such as “drip, rise, leakage and infiltration” is safer, more convenient, time-saving and reliable. Under the premise of not affecting the production progress, the leakage parts are treated online on standby, and the requirements of resealing and safe production are met, and the economic benefits are remarkable.

For more information about air compressors, remember to follow Kotech.

we offer a wide selection of high-quality air compressor packages in attractive prices, complete after sales, services with spare parts delivery within round a clock.