Double Screw Air Compressor PK Single Screw Air Compressor

Which is better? With the increasing progress of society and the rapid development of the economy, the market demand for air compressors has also been rising in recent years. So air compressor supplier also increased. Rotary screw compressor is widely used in various industries due to its high efficiency, low vibration, low noise and other advantages. So is it a single screw air compressor or a double screw ?

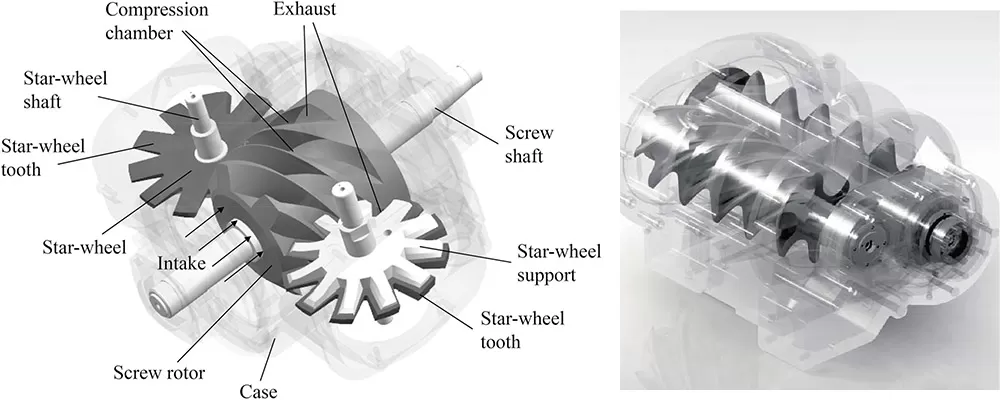

Single screw air compressor uses a single screw rotor to drive two symmetrical distribution of the star wheel rotation, relying on the screw groove and the inner wall of the shell to form a closed elementary volume, so that the gas to reach the required pressure. Simple structure, no unbalance force, no clearance volume, the rotor does not need coating.

Double oil injected screw air compressor is composed of a pair of parallel distribution, mutual engagement of the rotor, a rotor clockwise rotation, another counterclockwise rotation, in the process of mutual engagement to produce the required pressure, high mechanical reliability, good dynamic balance, strong applicability and so on.

Technically:

Among the oil-free screw air compressor, the current market share of double screws is about 90%, most of which are foreign brands. There is a strong R & D team, technical stability. The early star wheel material of single screw is not wear-resistant, so most of the equipment is unstable, and it has been upgraded in the past two years, and the stability has been greatly improved. However, the linear accuracy of the screw is high, the processing technology requirements are high, the production capacity is low, and the annual output value of the more well-known single screw air compressor supplier in China is about 50 million.

After-sales maintenance:

There is no lubrication in the compression chamber of the double screw air compressor, only lubricating oil in the gearbox, which can be said to be dry. The surface of the rotor is specially coated, the yin-yang rotor is not really in contact, so the first compression pressure is not very high, to increase the pressure, the use of secondary compression.

As a result, the internal structure is more complex, and special coatings also need to be repaired regularly, which is expensive to maintain.

Single screw is mostly water lubricated air compressor, the compressor lubrication medium is water, the use of water-based as a seal, completely oil-free, the output of pure oil-free compressed air.

Because it is to spray water into the compression chamber, the temperature is only about 40-50 degrees, approximate constant temperature compression, the volumetric efficiency is higher, and the efficiency is 15% higher than that of the dry oil-free screw air compressor. Oil-free water lubrication screw air compressor maintenance costs are low, only need to replace compressor spare parts (the water, water filter, air filter).

We will continue to work hard to optimize our oil-free water-lubricated screw air compressors to make our products more in line with the needs of the market.

Since I’ve talked about screw air compressors, what are the common problems with screw air compressor heads? And how much do you know?

The cause of fouling in air compressor water cooling systems

Cooling water is continuously recycled, water evaporation, concentration of various inorganic ions and organic substances, the entry of dust and debris, coupled with the increase in water temperature, on the one hand, the solubility of carbonate decreases, on the other hand, the CO2 overflow carbonate balance dissolved in water is destroyed, which promotes the formation of carbonate and accumulates on the surface of the heat exchanger and pipe wall to form dense carbonate scale.

The main hazards of air compressor heat exchange equipment fouling:

- Due to poor heat transfer, the long-term heat load on the heat transfer surface is too large, which can easily cause the mechanical properties of the heat exchange surface metal to be reduced.

- It is easy to cause corrosion and corrosion of household metals, further reducing the mechanical properties of metals.

- Heat exchange equipment pipe network “drum bag”, “cracks, leakage, burst pipes and other operational safety

Air compressor scaling treatment method:

The traditional cleaning method of air compressor heat exchanger: the physical method mainly uses manual scraping, grinding and high-pressure water scouring. The chemical method is that when there is already a situation where scaling affects heat conduction, it is generally to use pickling + high-pressure flushing to maintain the heat exchanger.

However, the descaling process is complex, and the quantity, solubility and treatment time of adding acid and alkali require the operator to have rich experience. Otherwise, it is easy to cause excessive corrosion and damage to heat exchange equipment and pipelines while descaling.

If you are looking for rotary screw air compressor manufacturer in China, you are in the right place. Kotech insists on proven manufacturing methods, full loading testing before shipping, and superior after sales service. Contact our sales person now.