When it comes to choosing a compressor for your business, the decision can be difficult. An axial or centrifugal compressor both have their own advantages and disadvantages, so it can be hard to decide which one is best for you. In this article, we will compare and contrast these two types of compressors so that you can make an informed decision.

1.What are the key differences between axial and centrifugal compressors?

Axial compressors are more common in industrial settings, while centrifugal compressors are more common in HVAC settings. Axial compressors are more efficient at compressing air than centrifugal compressors. Centrifugal compressors are more efficient at compressing gas than axial compressors.

2.How do you decide which type of compressor is best for your business?

When it comes to compressor types, there are many options to choose from. Stationary, portable, rotary, and reciprocating compressors are all available, each with their own unique benefits and drawbacks. How do you decide which type of compressor is best for your business?

The first step is to assess your needs. What will the compressor be used for? What are the business’s requirements for air quality, flow rate, and power consumption? Once you have a good idea of what you need, you can start researching the different types of compressors to find the best fit.

Stationary compressors are typically the best option for businesses with high-volume air needs. They are very reliable and can handle large amounts of air flow. However, they require a large amount of space and are not very portable.

Portable compressors are a good choice for businesses that need to move their compressor around often. They are small and lightweight, making them easy to transport, and they don’t require a lot of power to run. However, they typically have lower flow rates and air quality than stationary compressors.

Rotary compressors are a good option for businesses that need a lot of power in a small package. They are very compact and can generate a lot of air flow. However, they are not very reliable and require a lot of maintenance.

Reciprocating compressors are a good option for businesses that need a lot of air quality. They have high air flow rates and produce low levels of noise. However, they are not very efficient and require a lot of power to run.

Once you have determined the type of compressor that best suits your needs, you can begin researching.

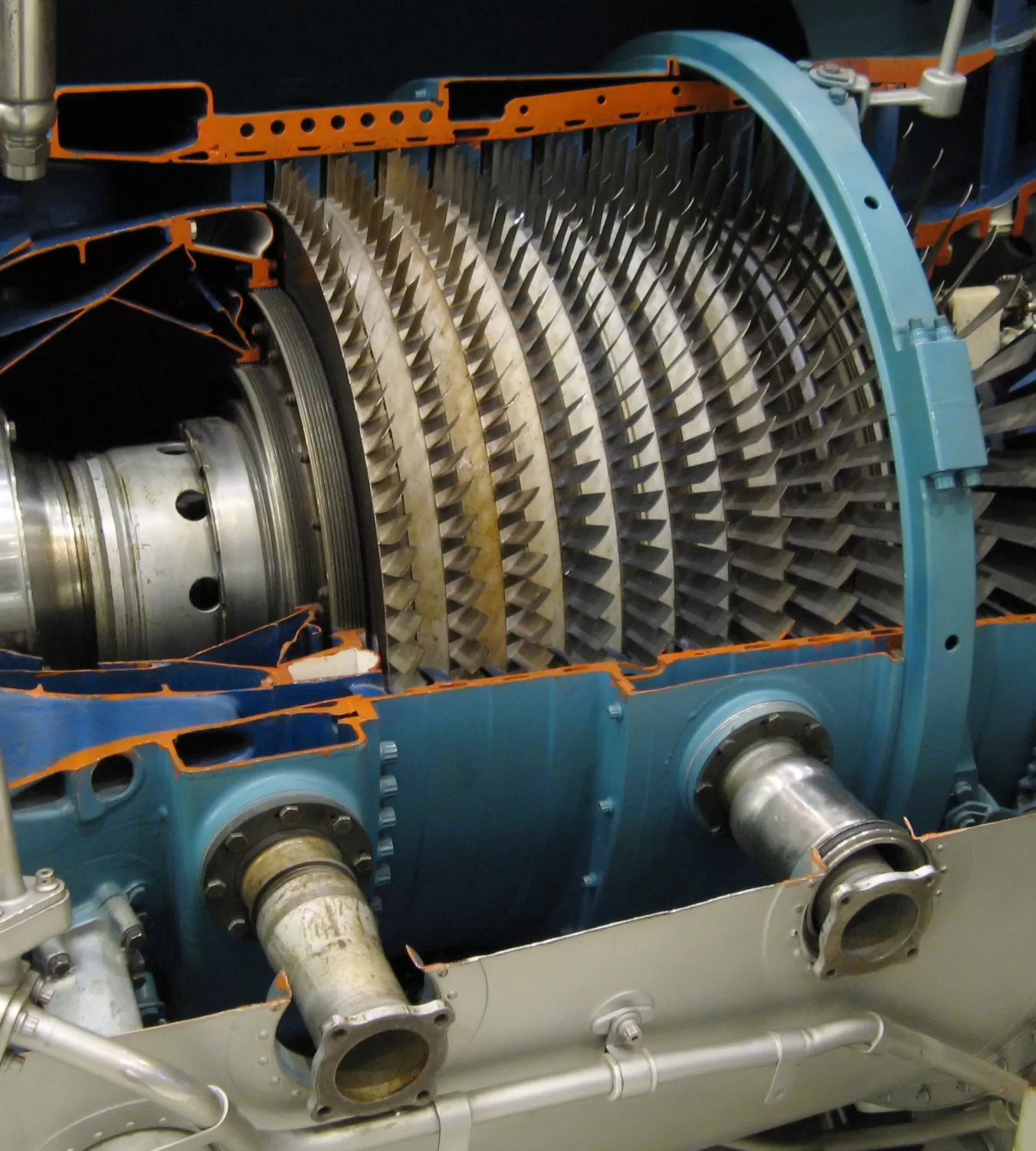

3.What are the benefits of using an Axial Compressor?

Axial Compressors offer a number of benefits over other types of compressors. They are more efficient, quieter, and smaller in size than centrifugal compressors. Additionally, axial compressors are less likely to cause cavitation and are easier to maintain.

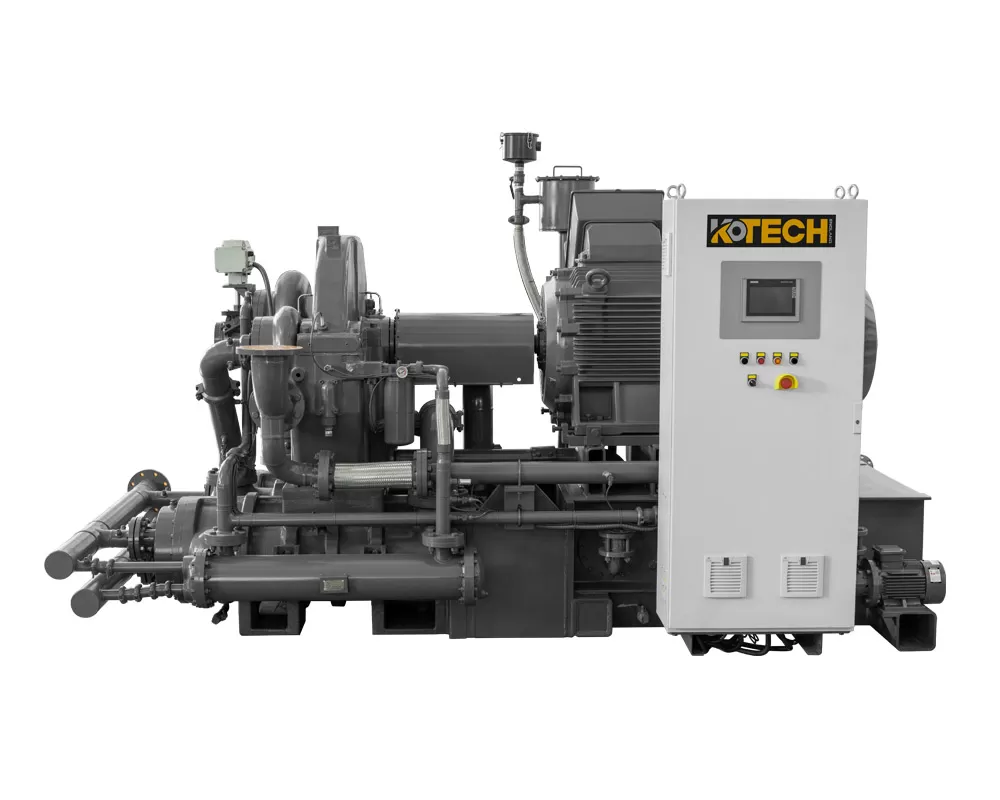

4.What are the benefits of using a Centrifugal Compressor?

Centrifugal Compressors offer a number of benefits over other types of compressors. They are typically more efficient, which can result in lower operating costs. They are also more reliable, and can handle a wider range of operating conditions. Additionally, centrifugal compressors are quieter and simpler to operate than other types of compressors.

5.Which compressor is right for you?

Picking the right compressor can be confusing. There are dozens of different models on the market, each with its own set of features. How do you know which one is right for you?

The first step is to figure out what you need the compressor for. If you’re just starting out, a basic model will be fine. If you’re a professional contractor, you’ll need a more powerful model with more features.

Once you know what you need, you can start narrowing down your choices. Compressors come in a variety of sizes, so you’ll need to pick the one that’s the right fit for your workspace.

Think about the power requirements, too. Some compressors require a lot of power, while others can run on a standard outlet.

Finally, consider the price. Compressors can range in price from a few hundred dollars to several thousand. Choose the one that’s within your budget.

With these factors in mind, you’re ready to choose the right compressor for you.

If you’re looking for an industrial air compressor system for your facility and you’re concerned about the complicated logistical decisions, we can make it easier— just give us a call and our experts will talk you through exactly what you need.