Analysis of working principle of screw air compressor oil system

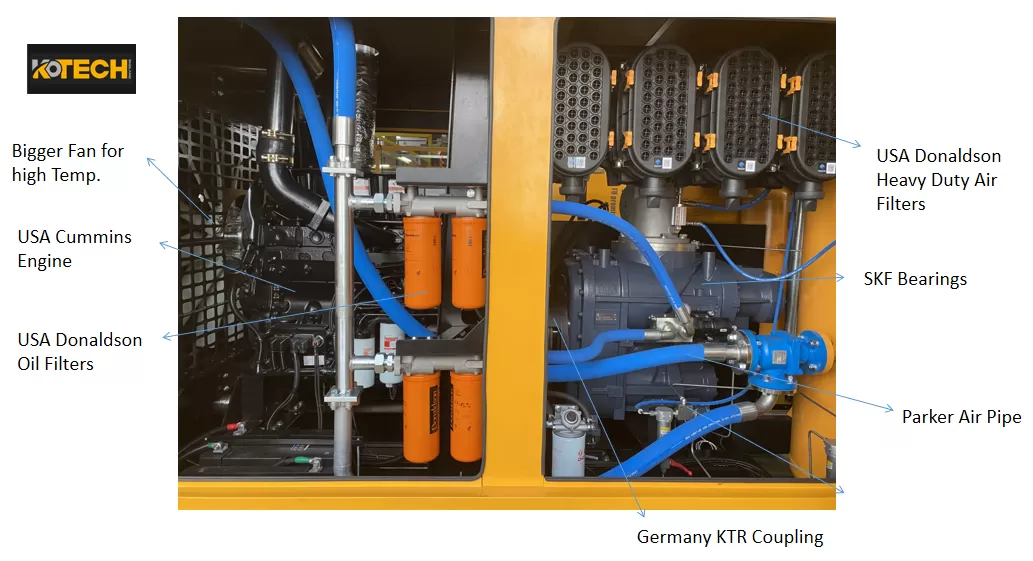

The oil system of screw air compressor includes oil tank, oil cooler, oil filter, oil cut-off valve, thermostat valve :

The lower volume of the oil and gas separator plays the role of the tank, and with a refueling hole, drain plug and oil level gauge.

Screw-type air compressor no hydraulic pump , the lubricating oil cycle is achieved by the pressure difference between the pressure before the filter element and the air end oil injection port. When compressor operation, the gas in the oil and gas separator under the action of the minimum pressure valve, first establish the pressure, force the lubricating oil through the oil cooler, and then through the oil filter into the oil valve, Supply oil to the upper and lower oil injection holes of the air end to take away the heat generated by the air in the process of compression, and lubricate and seal the working chamber of the air end to reduce the internal leakage.

The atomized oil injected into the compressor is mixed with air and compressed, and then re-enters the oil and gas separator through the exhaust check valve.

1.Screw air compressor oil system’s oil cooler

Oil cooler and air cooler cooling mode is the same, there are air cooling and water cooling two cooling mode. If the environment is not good, the fin of the air-cooled cooler is easy to be covered by dust and the cooling effect will be affected. In serious cases, the temperature of oil and gas will be too high and the screw air compressor will stop automatically. Therefore, low pressure air should be used regularly to blow the dust on the surface of the fin; If it cannot be blown clean, it must be cleaned with solvent, be sure to keep the cooling surface of the cooler clean.

When the pipes of water-cooled coolers are blocked, they must be soaked in solvent and mechanically removed from the clogged pipes to ensure complete cleaning.

2.Screw air compressor oil system’s oil filter

Oil filter equipped with differential pressure transmitter, its function is to remove impurities in the oil and keep the lubricating oil clean, so as to protect the operation of the air compressor air end. If the filter is blocked, it will lead to insufficient oil supply to the air end, so that the oil and gas temperature will rise, thus affecting the life of each moving part of the air end.

When the oil filter is blocked, the differential pressure transmitter will give indication and the signal light will be on. Stop the screw air compressor for inspection or replacement in time. Whether to replace the filter depends on the actual situation.

3.Oil cut-off valve

Oil valve is mainly composed of valve body, valve core, floating plug, spring and other components. Oil cut-off valve is one of the important components in the compressor, its working principle is: immediately after starting up, the high pressure chamber of the host engine is to supply gas to the end of the oil cut-off valve, the piston overcome the spring pressure, push the floating plug, that is, open the oil break valve spool, start to supply oil.

When the unit is running, the oil valve is always open; After the unit is shut down, the oil cut-off valve should be closed in time to prevent oil from flooding into the air end.

4.Thermostat valve

Water – cooled compressors are equipped with thermostat valve at the oil inlet of the cooler. Its function is to control the bypass flow of lubricating oil through the cooler and ensure that the oil and gas temperature of the compressor is higher than the pressure dew point temperature during load operation. Because the lower injection temperature will make the oil and gas temperature of the main engine too low, condensate water will be precipitated in the oil and gas separator and cooler, and it is not easy to be taken out by the air path system, and then deteriorate the quality of lubricating oil and shorten its service life.

The working principle of the thermostat valve is: at the beginning, the temperature of the lubricating oil is low, and the lubricating oil passes through the oil filter and the oil cut-off valve directly into the air end; If the oil and gas temperature rises to 71 degrees, the temperature sensing element in the thermostat valve extends, pushing the spool to move in the valve body; Start to close the bypass channel and gradually open the channel to the oil cooler. The ratio of the flow area between the two channels is determined by the oil and gas temperature. When the oil and gas temperature rises to 75 degrees, the side port is closed, and all the lubricating oil flows to the oil cooler for cooling cycle.

For more information about air compressors, remember to follow Kotech.

we offer a wide selection of high-quality air compressor packages in attractive prices, complete after sales, services with spare parts delivery within round a clock.